How to properly maintain wine barrels new and previously used?

BARREL MAINTENANCE INSTRUCTIONS

Using A New Barrel

New barrels are ready to fill immediately upon receipt. If you will not be filling the barrel immediately, be sure to keep it in a cool place. Avoid storing empty barrels in excessively moist places as this may allow mold to develop.

PREPARATION FOR WINE

Water Soak & Test

It is important to follow these re-hydration and inspection steps when you are going to fill the barrel immediately with wine.

Option 1:

1. Fill the barrel with 3-5 gallons of filtered, chlorine-free, hot water. Use the hottest water possible, with 180°F or 82°C the ideal temperature.

2. Place a silicone bung in bunghole.

3. Rotate the barrel from side to side, completely wetting the barrel’s interior.

4. Stand the barrel upright on one head up to 4 hours to completely hydrate the head. 5. Rotate and stand upright on the other head up to 4 hours repeating the hydration 6. Check for leakage. See instructions below if present.

7. Empty the barrel and allow it to drain and dry completely (approximately 1 hour).

Option 2 (Cold Water/High Volume):

1. Completely fill the barrel with filtered, chlorine-free, cold water.

2. Let the barrel re-hydrate for 24 to 48 hours.

3. Check for leakage. See instructions below if present.

4. Empty the barrel and allow it to drain and dry completely (approximately 1 hour).

Check for Leakage

If leakage is present, drain the barrel and allow it to dry completely (approximately 1 hour).

With chalk, circle the area where the leakage was present. Examine that this exterior area is completely dry. Repeat Option 1 or Option 2 above and re-examine for leakage.

If the leakage continues call us. Empty the barrel, allow it to drain and dry completely, treat each barrel with 10- 20 grams of sulfur sticks (or the equivalent in gas form), and re-insert the bung. Again, be certain the barrel is completely dry prior to sulfur treatment.

Remember that water should not sit in a barrel for more than 48 hours without sulfur and citric acid. Also, use caution when removing bung due to internal pressure build-up.

Empty Storage Of Previously Filled Barrels

Cleaning and Storing between Wine Fills

Dry Storage- Method 1

Stage 1

1. Barrels should be visibly clean and in good condition.

2. Set barrels outside, properly rinse and drain for one hour.

3. Rotate to locate bung at 12 o’clock position.

4. Sulfur gas for approximately 3 seconds (one half of a sulfur stick is equivalent to 3 seconds of gasing at

15-20 PSI) and leave barrel in this position for one hour with a paper cup in the bung.

5. After one hour, remove cup and rotate bung hole to 6 o’clock to ensure proper drying during storage. 6. Barrels should then be left outside for 24 hours to allow sulfur gas to disperse.

7. Move barrels back inside the next day for storage and leave un-bunged.

8. This process should be sufficient for a minimum of 4 weeks.

Stage 2

1. After 4 weeks move the barrels back outside.

2. Again sulfur gas for approximately 3 seconds.

3. Insert paper cup in the bung hole for one hour to allow gas to warm up, remove paper cup, leave barrel

outside for 24 hours and then move the barrel back inside. Barrels are then stored un-bunged at 3 or 9

o’clock.

4. Complete Option 1 or 2 PREPARATION FOR WINE prior to refilling with wine.

NOTES:

When using this method it is important that you have a facility that is fairly humid (at least 60%) to maintain the barrel while storing empty. The advantage of this method is that it allows a minimal amount of sulfur to be absorbed by and retained in the empty barrel. Research also suggests a minimum amount of volatile acid present in the barrel after storing barrels in this manner.

Dry Storage- Method 2

1. Barrels should be visibly clean and in good condition.

2. Barrels should be properly rinsed and drained for one hour.

3. Barrels should then be sulfur gassed for 3 seconds (one half of a sulfur stick is equivalent to 3 seconds of gasing at 15-20 PSI) and then sealed with a wooden bung. When using sulfur sticks be sure not to allow

any sulfur drippings to fall into the barrel.

4. Barrels should then be checked and re-sulfured every 5 to 6 weeks as needed.

5. Prior to refilling with wine it is important to soak the barrel with hot water (140 degrees) prior to using to

remove as much remaining sulfur as possible.

NOTES:

This method lends itself to a higher rate of volatile acid than Dry Storage- Method 1. Larger amounts of sulfur seem to be absorbed by the wood using this method than Dry Storage- Method 1.

Cleaning and Storing between Wine Fills

Wet Storage Method

1. Barrels should be visibly clean and in good condition.

2. Barrels should be properly rinsed and drained for one hour.

3. Fill the barrel 2/3’s full with water.

4. For every liter of barrel volume, you will need to add 1 gram of citric acid and 2 grams of Potassium

Metabisulfite. Mix this solution in a separate container with a small quantity of warm water so that it is

completely dissolved. Beware of fumes and work in a well ventilated area.

5. Add the solution to the barrel, fill the barrel up with water, and insert a bung.

6. You will need to top off the barrel with more of the holding solution every 4 to 6 weeks.

NOTES:

When using this method the water solution will extract a considerable amount of the barrels oak character and more sulfur will be absorbed into the wood as compared to the other methods.

Sanitizing A Barrel That Has Already Been Used

Use this procedure to sanitize your barrel before filling it with wine.

1. Fill barrel halfway with cold water.

2. Add 2.5 grams of Potassium Metabisulphite for every liter of the barrel’s total volume.

3. Add 1.25 grams of citric acid for every liter of the barrel’s total volume.

4. Bung the barrel. Roll it to mix in the Potassium Metabisulphite and citric acid.

5. Remove bung and finish filling barrel with cold water. Replace bung and let full barrel stand 48 hours. 6. Drain barrel. Rinse several times with cold water.

Refurbished ReCoop French Oak Barrels

All ReCoop barrels are thoroughly tested for water tightness and structural integrity prior to shipment. Handle the barrel carefully and avoid rough treatment that could displace staves. In accordance with good wine making procedures, barrels should be stored off the ground in a cool, well ventilated cellar away from direct sunlight to prevent mold growth and excessive temperature swings. All ReCoop barrels are tested, rinsed and sulfured be- fore shipment, do not attempt to smell the barrel without evacuating all sulfur from within the barrel. Caution: do not smell the barrel before evacuating the sulfur.

Preparing Your Barrel For Use:

Your barrel must be rehydrated prior to putting wine into it. One of the two following procedures can be used to re-hydrate a barrel.

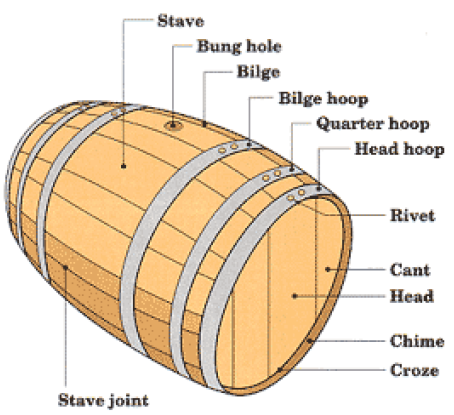

Head Soak: Use only chlorine free, clean, potable water. While standing the barrel upright, fill the barrel with 1/10th its capacity with water. Cover the bung hole and roll the barrel 5-8 times to wet the inside of the barrel. Stand the barrel once again and put water on the head up to the top of the chime. After 4-8 hours, once again, roll the barrel 5-8 times and this time stand it on the other head and top the head with water up to the chime. Let stand for an additional 4-8 hours, then remove all water. Once all water is removed the barrel should be filled with wine immediately. If the barrel is not filled immediately after all water is removed, gas with sulfur or burn a sulfur strip to prevent any mold or fungus growth.

Total Fill: An alternative method is to fill the barrel completely with water and let stand until the barrel swells. Once leak free your barrel is ready to be filled with wine.